We are Committed to Energy Conservation

Sinclar has a long history of finding new energy solutions that sustainably reuse our resources and reduce carbon emissions. As a pioneer in North America, Sinclar was one of the first forestry companies in BC developing and delivering low carbon energy solutions. For decades, we have led sustainable energy initiatives and continue to innovate our operations and business model to be at the forefront of a low carbon future.

Our biomass energy systems take the equivalent of 7,800 cars off the road every year.

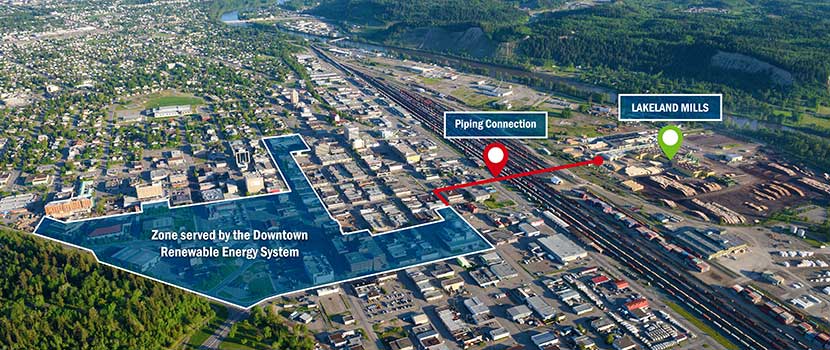

The Downtown Renewable Energy System reduces carbon emissions in the City of Prince George, removing the equivalent of 400 cars from the road each year.

Nechako Green Energy produces clean energy from wood residuals equivalent to the amount of electricity used by over 1,400 homes each year

Sustainable Energy Powering our Mills and Communities

We operate bioenergy systems at all three of our lumber operations and Premium Pellet. The bioenergy systems convert wood waste into energy, using residual wood to heat our mills, wood drying kilns, and buildings in our community.

Our sustainable energy systems divert what once ended up in beehive burners or landfills to produce low carbon energy. The result is lower energy consumption, better air quality, and less carbon dioxide in the atmosphere.

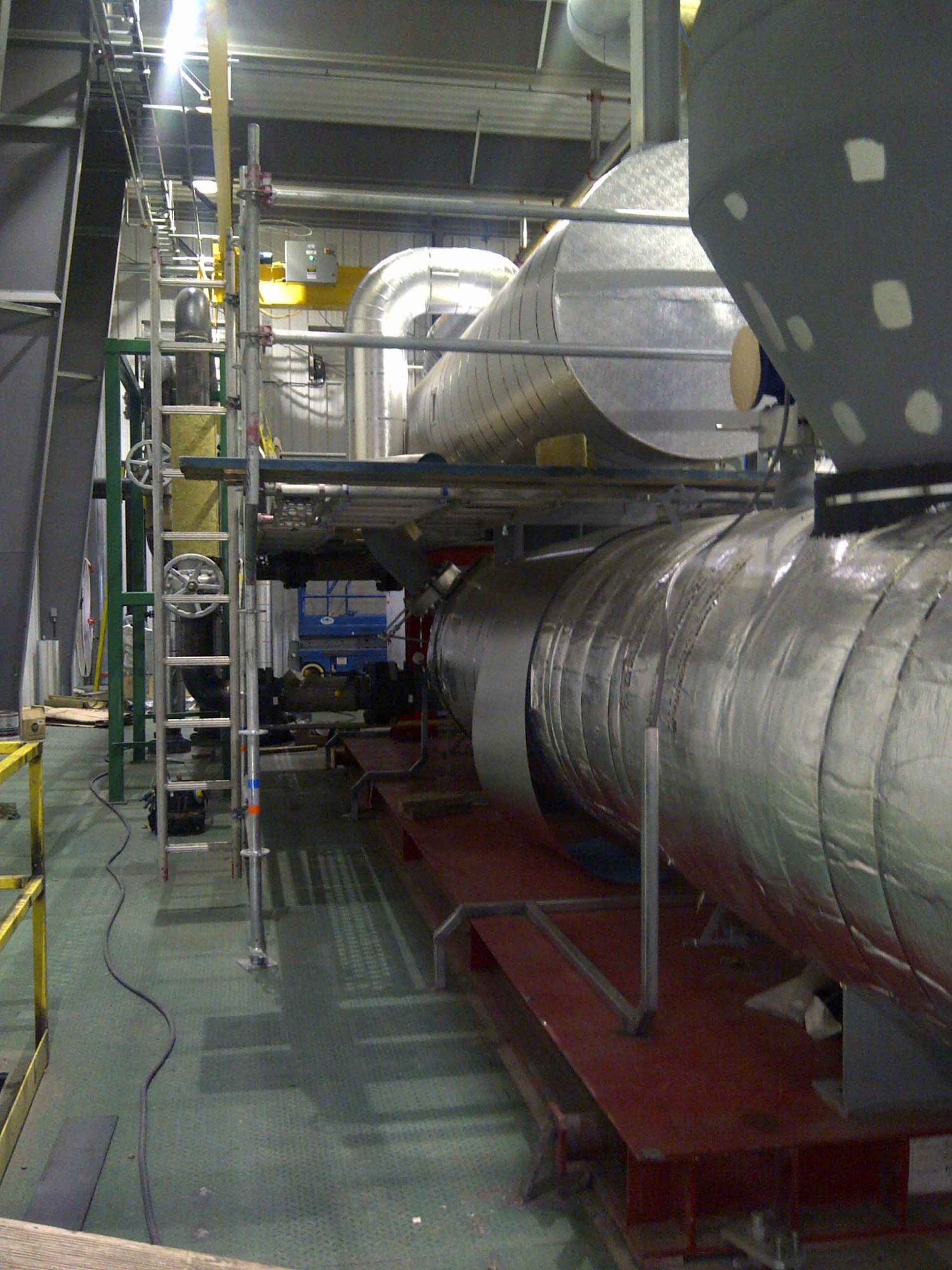

Nechako Energy System

It started with a simple question – is there a better use for what we consider waste? We evaluated the wood waste we generated and the energy requirements at the Nechako mill and found that there was a surplus. This discovery sparked a partnership opportunity with BC Hydro, where we co-developed the biomass electricity generation system, Nechako Green Energy (NGE). Nechako Green Energy uses Organic Rankine Cycle processes to turn surplus heat energy into electricity that is used to offset internal consumption at Premium Pellet. The sustainable energy generated by Nechako powers the equivalent of over 1,400 homes each year.

How it works

- Burns wood waste (bark) to generate heat, which is transferred to a fluid and circulated across the site

- The heat is used for kiln drying lumber (the site does not use natural gas for lumber drying)

- The heat is also used for space heating across the mill site, which reduces natural gas consumption

- Then, the surplus heat is provided to the Organic Rankine Cycle to generate electricity (NGE)

Lakeland Energy System

How it works

- Burns wood waste (bark) to generate heat, which is transferred to a fluid and circulated across the site

- The heat is used for kiln drying lumber (the site does not use natural gas for lumber drying)

- The heat is also used for space heating across the mill site. Thanks to the advanced use of wood waste for energy, Lakeland does not use any natural gas

- Then, the surplus heat is used to power the Downtown Renewable Energy System for the City of Prince George

Apollo Energy System

How it works

- Burns white wood waste (shavings) to generate heat, which is transferred to a fluid to be circulated across the site

- The heat is used for kiln drying lumber (the site does not use natural gas for lumber drying)

- The heat is also used for space heating across the mill site, which reduces natural gas consumption

Bioenergy Partnerships

Downtown Renewable Energy System,

City of Prince George

We partner with the City of Prince George to help provide sustainable energy to the community. The Downtown Renewable Energy System reduces carbon emissions in the City of Prince George, removing the equivalent of 400 cars from the road each year.

Together we pipe hot water to several downtown buildings to provide heat and hot water. The plant and equipment, including state of the art emission controls, has been installed at the Lakeland mill site and is owned by the city. Lakeland supplies the wood fibre and maintains and operates the plant and equipment.

As more buildings are connected to the Downtown Renewable Energy System, Lakeland and Sinclar will support the community to continue lowering its carbon emissions.

University of Northern BC

Gasification System

Lakeland Mills also supplies fibre for the sustainable energy system that heats the University of Northern BC. We supply over 4,000 bone dry tonnes of sawmill residue per year to fuel the gasification system at the university. The bioenergy plant heats the core campus buildings, offsetting roughly 85% of the fossil fuels previously used.

Excellence In Sustainability

Sinclar has been involved in the BC Hydro Industrial Energy Management program since 2009. This program includes:

- Hiring an Energy Manager

- Assessing energy management maturity and capacity through an Energy Management Assessment

- Developing a Strategic Energy Management Plan including: assessing baseline energy consumption, developing energy maps to identify how each of the their facilities use energy, setting energy reduction targets, creating actions to meet targets

- Tracking progress, improvement, and reporting

- Incentive funding for energy conservation projects and studies

To learn more about BC Hydro energy management programs, including Industrial Energy Management, click here.